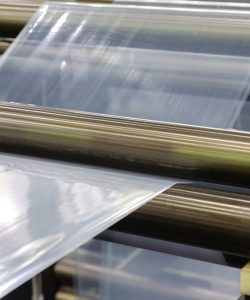

Extruded PE Film

PE Shrink Film

Plastic film extrusion is one of the most important processes in our industry. It accounts for around a quarter of all thermoplastics consumed and the film extruded is almost entirely for consumption in packaging – particularly food packaging – with the remainder going into agricultural and construction applications.

In its simplest form, the process involves pushing molten polymer through a circular or slot die. This continuous process enables the production of a consistent high quality product to extremely accurate gauge. For most thin gauge films, the film extrusion process takes the form of blown or cast extrusion.

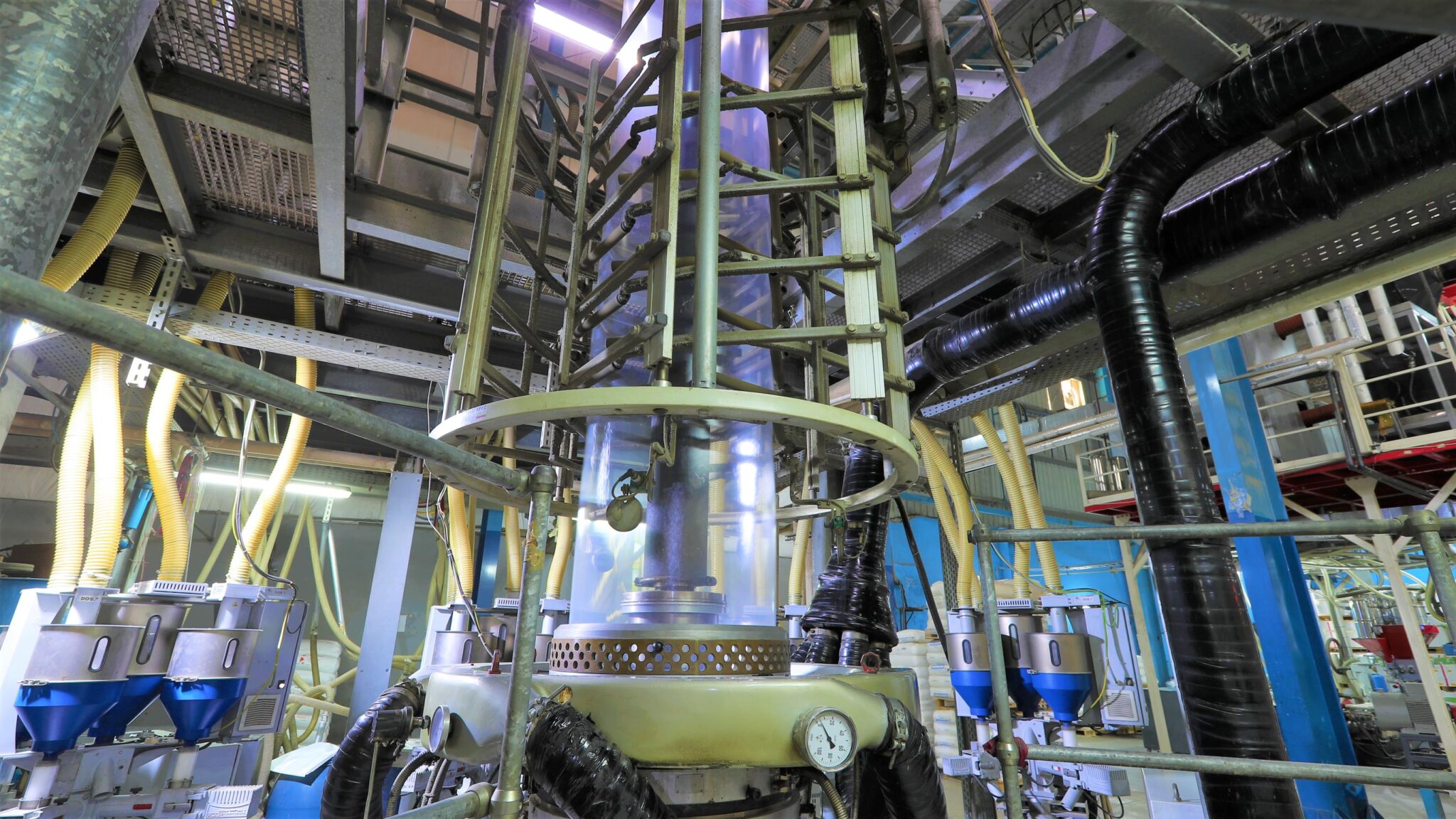

Reifenhauser Blown Line 5-Layer:

- Reifenhauser providing as Technical Solution for Today’s and Tomorrow’s Polyethylene and Barrier with Nylon /EVOH Film Production.

- High-tech systems with modular design, we bring out the best in blown film technology to meet the requirements of each product. For products with very high quality requirements.

- Producing precise layer thicknesses. Achieve outstanding basic tolerances, precise individual layer thicknesses and offer utmost flexibility.

- World renowned gravimetric dosing system make us capable to design precise blends of materials according to customer need and automatic module of system control the grammage of film.

- Best online thickness profile control system outcomes as best film quality.

- Central winding station with multistage tension control mechanism make us able to provide good winding quality

- Best Cooling systems give us controls for the clarity.

- Adding values to Printability / Register Accuracy – Printing Speed – Lamination Quality.

- Design Film Properties – Down Gauging – Improve mechanics – Optimized Optics – Increased barrier properties.

We can produce film for:

Form Fill Seal Pouches for | Extruded PE Film (Transparent, Milky, Nylon Range) |

Stand up Pouches | Frozen Food Packaging |

Barrier Packaging | Shrink Wrap |

Our PE Shrink Film and PE Shrink Wrap are very popular with consumer, retail and industrial manufacturers for packaging both edible and non-edible products.

Our PE Shrink Film is durable, enables a strong seal, and is a very cost-effective packaging solution.

Sustainability is a key core value at SPI and our PE Shrink Films are environment-friendly. SPI PE Films are specially formulated based on the client’s needs.

Advantages:

- Strong seal

- Excellent Clarity and gloss

- Broad heat seal range

- Allows for surface printing

- Environment-friendly.

- Reduces the need for plastic

- lower carbon footprint than traditional external packaging

- Cost-effective: 60 – 75% lower cost than other packaging material eg cardboard or plastic and lower transport and handling costs

- Good antistatic property

- Excellent hot tac

- Durable and tough. Easily able to withstand transport, handling and storage

- Resistant to tearing and puncture

Our Products:

We are leading producers of PE films which are available in different thickness and customized according to your needs. General PE properties are listed below for information.

Transparent, Colored or White Opaque Film for Printed Bags. | White Opaque Film for Detergent Powder with High Moisture Barrier. |

Transparent Film for the Laminate of Rice, Flour, Lintels, Powders, Spices ETC | High Oxygen Barrier Transparent Film with Nylon for Edible Oil, Cheese, Yeast ETC |

Very High Oxygen & Moisture Barrier Film with EVOH for UHT Milk, Processed Meat. | Black and White Opaque Film for Pasteurized Milk and Courier Bags. |

Transparent and White Opaque Film for the Laminates of Hot Filling Liquid and Paste. | Transparent Shrink Film for Water and Beverage Crates. |

Transparent Shrink Film for Jumbo Rolls of Textile Fabrics. | Oxy Biodegradable Transparent Film for Bread Bags & other uses. |

UV Resistant Film for Greenhouses. | Transparent Film for Bundling Mulch Film for Agriculture Field. |